◊ Introduction

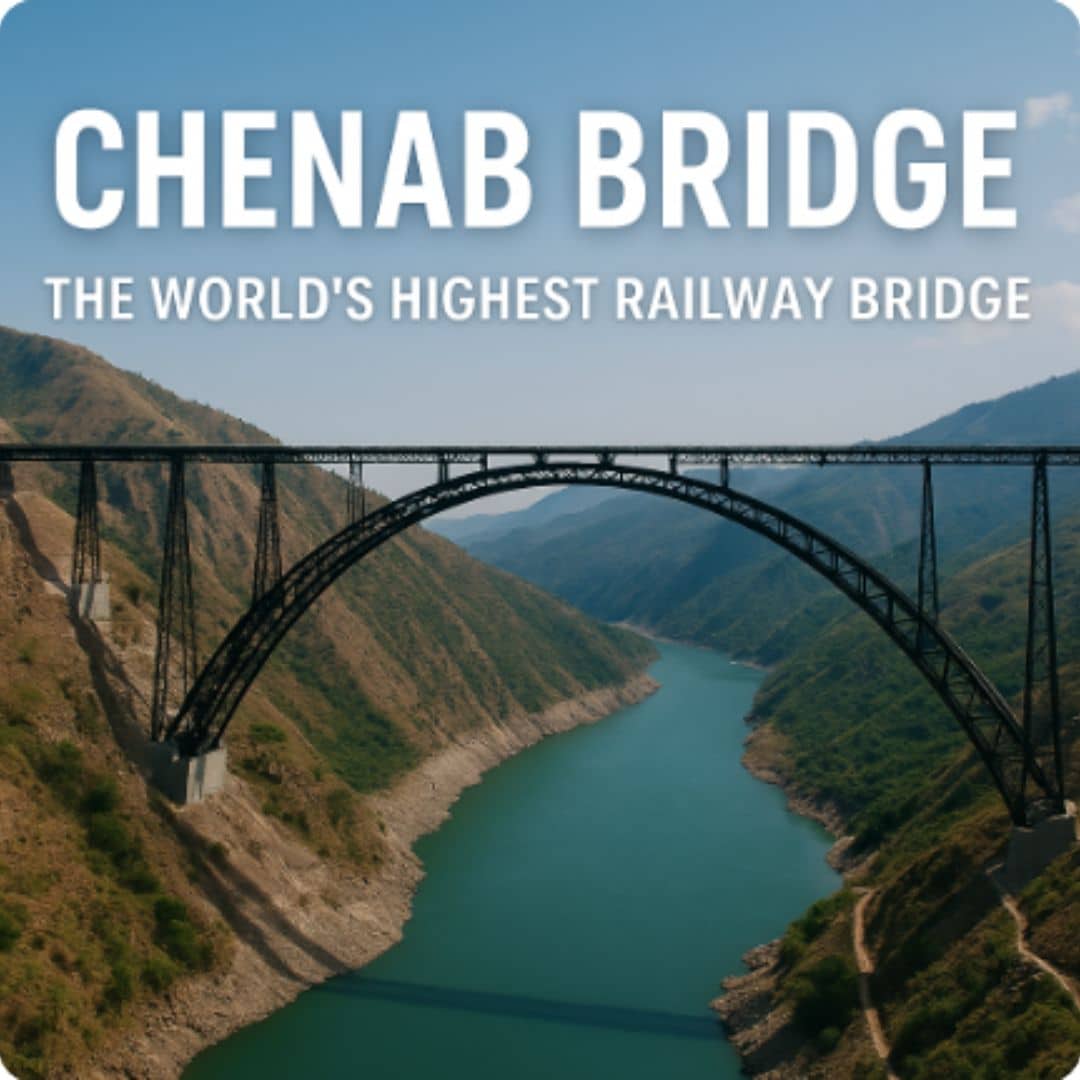

Chenab Bridge is not just a railway bridge—it is a symbol of India’s technological and engineering prowess. This incredible bridge, located in the Reasi district of Jammu and Kashmir, is built over the Chenab River and is currently recognized as the world’s highest railway bridge. The Chenab Bridge height is 359 meters above the river, which is higher than the Eiffel Tower—it is undoubtedly an engineering marvel in India.

Discover Chenab Bridge, the world’s highest railway bridge. Learn its tech, design & impact on India’s rail infrastructure. Read more now!

This Chenab Bridge railway line is an important part of India’s Udhampur-Srinagar-Baramulla railway project. Built to connect the remote hilly region, this steel arch bridge uses cutting-edge bridge technology. Overcoming harsh weather conditions, earthquake-prone areas, and hostile environments, the Chenab Bridge construction is a milestone in Indian railway engineering.

Today, Chenab Bridge latest news, amazing Chenab Bridge facts, and drone views have captured the world’s attention and are carrying a strong message of Indian infrastructure development.

◊ What Is the Chenab Bridge?

Chenab Bridge is a state-of-the-art railway bridge located in the Reasi district of Jammu and Kashmir, India, built over the Chenab River. It is not only the highest railway bridge in India, but also in the world, with a height of about 359 meters above the river level. This bridge is part of the Udhampur-Srinagar-Baramulla railway line project, which is being built with the aim of connecting the remote hilly areas of the northern part of the country with the mainland by rail.

This bridge is a steel arch bridge, i.e., a huge bow-shaped steel arch, which properly balances the load and pressure of the bridge. Since it is built in an earthquake-prone and risky area, the world’s most modern engineering and construction technology has been used here.

The Chenab Bridge is not just a railway bridge—it is a living reflection of India’s bold technological and engineering achievements. This bridge has been built with unprecedented success, overcoming natural adversities, complex geographical environment and construction challenges. Through this, India has once again proven that when advanced technology and a strong mindset work together, any impossible thing in the world can be made possible.

This project is not only a new horizon of connectivity for the northern part of India, but also a historical example of modern infrastructure development. Therefore, the Chenab Bridge today is not just an achievement of engineering, it is a symbol of national pride, indigenous talent and self-confidence.

| Feature | Description |

|---|---|

| Location | Bakkal, Reasi district, Jammu & Kashmir, India |

| River Spanned | Chenab River |

| Bridge Type | Steel Arch Bridge |

| Height Above River | 359 meters (1,178 feet) — taller than the Eiffel Tower |

| Total Length | 1,315 meters (4,314 feet) |

| Main Arch Span | 467 meters (1,532 feet) |

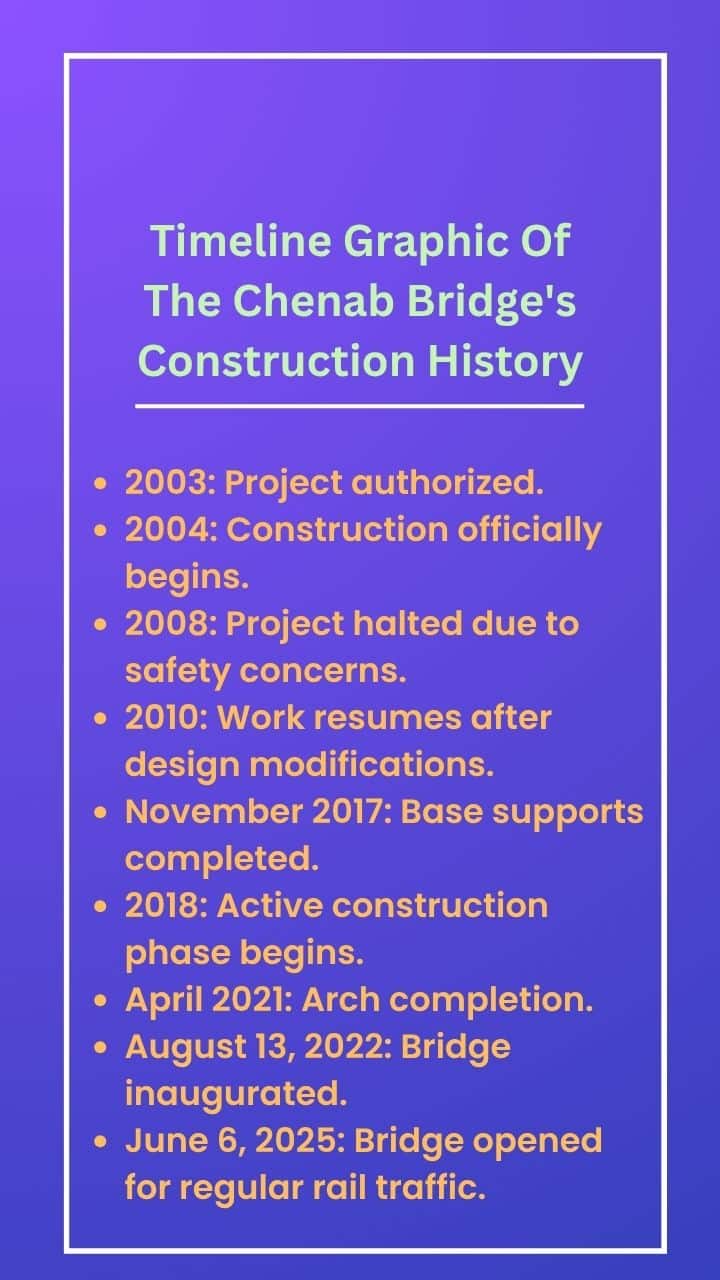

| Construction Started | 2004 |

| Completed | 2022 (operations expected from 2024 onward) |

| Steel Used | Approx. 28,600 tons |

| Wind Resistance | Up to 266 km/h |

| Seismic Safety | Earthquake-resistant design |

| Blast Safety | Blast-resistant technology used (first in Indian Railways) |

| Part of Project | Udhampur–Srinagar–Baramulla Rail Link (USBRL) |

| Purpose | Connectivity, defense logistics, tourism, and economic development |

| Unique Recognition | World’s highest railway bridge |

| Symbolism | Icon of India’s engineering strength and infrastructure innovation |

◊ Key Technical Facts

The Chenab Bridge has set a world record not only in height but also in construction techniques and engineering skills. It is built over the Chenab River, which has a height of about 359 meters above the river surface—making it known as the highest railway bridge in the world. Surprisingly, this bridge is taller than the Eiffel Tower. Building such a huge infrastructure in such a remote and earthquake-prone area is undoubtedly an example of the ultimate achievement of Indian engineering.

The entire bridge is about 1,315 meters long, and its central arch or main arch is 467 meters long. About 28,600 tons of high-quality steel have been used in the bridge, which makes it very strong and durable. The bridge is a steel arch design, which is firmly built between two mountains and specially made pillars have been placed at both ends, which maintain balance. Technology has been used in the construction that is capable of resisting earthquakes and strong gusts of wind. It can also withstand a wind speed of 266 km per hour. The most notable thing is that this bridge has been used in blast-resistant technology, which is used for the first time on Indian railways. All these elements have made the Chenab Bridge a unique example of technology not only in India but also in the entire world.

◊ Engineering Challenges and Innovations

The construction of the Chenab Bridge was a huge engineering challenge. The bridge is located in the mountainous region of Jammu and Kashmir, India, where landslides, earthquakes, and severe weather are almost a regular occurrence. To build such a high railway bridge in such a hostile environment, advanced technology and innovative techniques had to be used beyond conventional methods.

The first major challenge was establishing the foundation of the bridge, because the hilly soil is not always stable. Therefore, a different construction technique was taken using modern vibration control technology and strong pillars. The second major challenge was to resist strong winds and earthquakes. For this reason, the bridge has been designed in such a way that it can withstand winds of 266 km per hour and earthquakes.

The biggest innovation was the blast-resistant design—the first time it has been used in a railway bridge in India. In addition, due to the height, the construction work relied on drones and robotic technology, which ensures safety and precision.

All these innovative steps have made the Chenab Bridge a world-class technological success.

◊ Constructor and History of Chenab Bridge:

The Chenab Bridge was built by Konkan Railway Corporation Limited (KRCL), a subsidiary of Indian Railways, in collaboration with Afcons Infrastructure (a part of the Shapoorji Pallonji Group) and other global engineering consultants. The project is part of the Udhampur-Srinagar-Baramulla Rail Link (USBRL).

| Role | Name/Organization |

|---|---|

| Main Authority | Indian Railways |

| Executing Agency | Konkan Railway Corporation Limited (KRCL) |

| Main Contractor | Afcons Infrastructure |

| Design Support | DRDO (for blast resistance) |

| Consultants | DMRC, IIT Roorkee, international experts |

| Fabrication & Erection | Megha Engineering and Infrastructure Ltd. |

Historical Background: Why was the Chenab Bridge built?

Strategic Need:

Considering the strategic and defense importance of Jammu and Kashmir, the idea of connecting the Kashmir Valley with the rest of India by rail was proposed decades ago.

Magnificent Terrain:

Rugged Himalayan terrain, deep gorges, and unstable geology had made previous attempts difficult. Until now, Kashmir was not fully connected by rail, which limited both economic and military supplies.

Visionary Project:

The bridge is part of the USBRL project, which began in the early 2000s, which aimed to lay 272 kilometers of railways across one of the most challenging terrains in the world.

Symbol of Integration:

The Chenab Bridge symbolizes the integration of Jammu and Kashmir into the national rail network, promoting economic development, tourism, and social cohesion.

Delayed but steadfast:

Construction work began in 2004, faced multiple delays due to technical, political, and climatic issues, and was finally completed in 2022. It stands today as an engineering marvel.

◊ Construction Technology Used

The Chenab Bridge has been constructed using sophisticated and complex engineering technology, which has opened a new horizon in the history of Indian railways. It is a steel arch bridge, where a huge bow-like steel structure has been used between two mountains. This type of design maintains balance and remains stable even in strong winds and earthquakes.

Its height is the first challenge of this bridge construction. Working at a height of 359 meters is very dangerous. Therefore, Cable Crane System is used there, which is one of the longest cable crane systems in the world. Through this, the supply of materials and the installation of work platforms are much easier.

In addition, drones and sensor technology have been used where people cannot normally reach. Modern GPS and Geo-technical Monitoring Systems are used in construction monitoring, so that each part is placed perfectly.

To ensure the safety of the bridge, blast-resistant technology has been used here, which protects it from explosions or attacks. Moreover, the foundation construction is planned with the help of Hydraulic Simulation Modeling, keeping in mind the flow of the river and geographical location.

Above all, the bridge is made of Weathering Steel, which can last for a long time without rusting. It provides greater durability with less maintenance.

All of this combined makes the Chenab Bridge a remarkable feat of technology and construction techniques, a model for the future.

◊ Why It Matters for India’s Infrastructure

The Chenab Bridge is not just a railway bridge—it is a symbol of India’s infrastructural development, which has created new horizons in the country’s connectivity, security, tourism and economic development. It is part of the Udhampur-Srinagar-Baramulla Railway Project, which aims to fully connect Jammu and Kashmir with the country’s main railway network.

This bridge has made it possible to easily transport goods and passengers in remote hilly areas and border areas, which was previously impossible. As a result, logistical support for the military has become faster and more effective, especially in strategically important border areas.

Moreover, this bridge will boost economic development, employment and tourism at the local level. As the highest railway bridge in the world, the Chenab Bridge will become an attractive destination for tourists, which will benefit local businesses and the hotel industry.

From a technological perspective, the Chenab Bridge has taken India to a stage where the country is now able to implement one of the world’s most difficult projects with its own advanced construction technology. This is the best reflection of the “Atmanirbhar Bharat” initiative.

All in all, the Chenab Bridge is not just a construction project, but rather a blueprint for India’s future infrastructure, paving the way for modernity, safety, and progress.

◊ Tech Behind the Structure: Lessons from Chenab Bridge

The construction of the Chenab Bridge is not only a remarkable piece of architecture, but also a real example of the successful application of modern technology, which will serve as a guide for the construction industry of the future. At every stage of the construction of this bridge, technologies have been used that will guide the development of future infrastructure. This bridge has clearly demonstrated how safe and sustainable infrastructure can be built in earthquake-prone, mountainous and border regions like India.

The first important lesson is the proper use of technology to deal with geo-natural hazards. Special earthquake-resistant designs have been used here, which can be ideal for the construction of large bridges or railways in the future.

The second lesson is digital control and inspection technology. GPS, sensors, drones and robotic construction assistance have been used in the construction of the bridge, which has made working at heights and inaccessibility easier and safer.

Another important aspect is the blast-proof design—the Chenab Bridge is the first railway bridge in India where this technology has been used. Through this, it will be possible to set new standards of safety in military and strategic installations in the future.

The most important lesson is to make the right combination between the local environment, technology and manpower in large projects. The Chenab Bridge has shown that the impossible can be made possible with proper planning and the use of modern technology. This bridge is not just a construction, it has become a living textbook for future engineering education.

◊ Conclusion

The Chenab Bridge is not just a railway bridge—it is a symbol of engineering, technology and indomitable spirit of modern India. The construction of this bridge in a remote mountainous region, amidst a hostile natural environment, proves that even the impossible can be made possible when planning, technology and skilled manpower work together. It is a milestone in the history of Indian Railways, which is taking not only the communication system, but also the country’s security and economy to new heights.

As the world’s highest railway bridge, the Chenab Bridge is not only a pride of India, but also an exceptional example of India’s engineering prowess, showcasing our technological advancements to the world. The innovative design, advanced technology and creative thinking used in its construction will be a source of inspiration for future infrastructure development.

◊ FAQs:

1. What is the Chenab Bridge?

Answer: Chenab Bridge is the world’s highest railway bridge built over the Chenab River in Jammu and Kashmir, India, which is part of the Udhampur-Srinagar-Baramulla Railway Project.

2. What was the main purpose of building Chenab Bridge?

Answer: The main goal was to connect Jammu and Kashmir to India’s rail network, facilitate military and civilian movement, and ensure strategic development.

3. When did its construction start and end?

Answer: Construction work began in 2004 and was completed by the end of 2022, although rail traffic will start from 2024.

4. What type of bridge is Chenab Bridge?

Answer: It is a steel arch bridge, where an arch-shaped steel structure has been used.

5. How many tons of steel have been used in Chenab Bridge?

Answer: About 28,600 tons of steel have been used in this bridge.

6. Why is it the highest railway bridge in the world?

Answer: Due to its height and architectural structure, it is taller than the Eiffel Tower, which has established it as the highest railway bridge in the world.

7. Is this bridge earthquake or storm resistant?

Answer: Yes, it is earthquake resistant and can withstand winds of 266 km/h.

8. What special technology has been used in Chenab Bridge?

Answer: Blast-resistant technology, Cable crane system, GPS monitoring, Weathering steel and Geo-technical sensors have been used.

9. How important is this bridge for tourism?

Answer: Being the highest railway bridge in the world, it will become a huge tourist attraction, which will have a positive impact on the local economy.

10. What message does the Chenab Bridge send for future infrastructure development?

Answer: It proves that any difficult project can be successfully implemented through technology, planning and innovation.